RDC2 Platform

Roding Driving Chassis 2 Platform

Als Systemlieferant ist RODING Mobility der perfekte Partner für Ihre Gesamtfahrzeugprojekte.

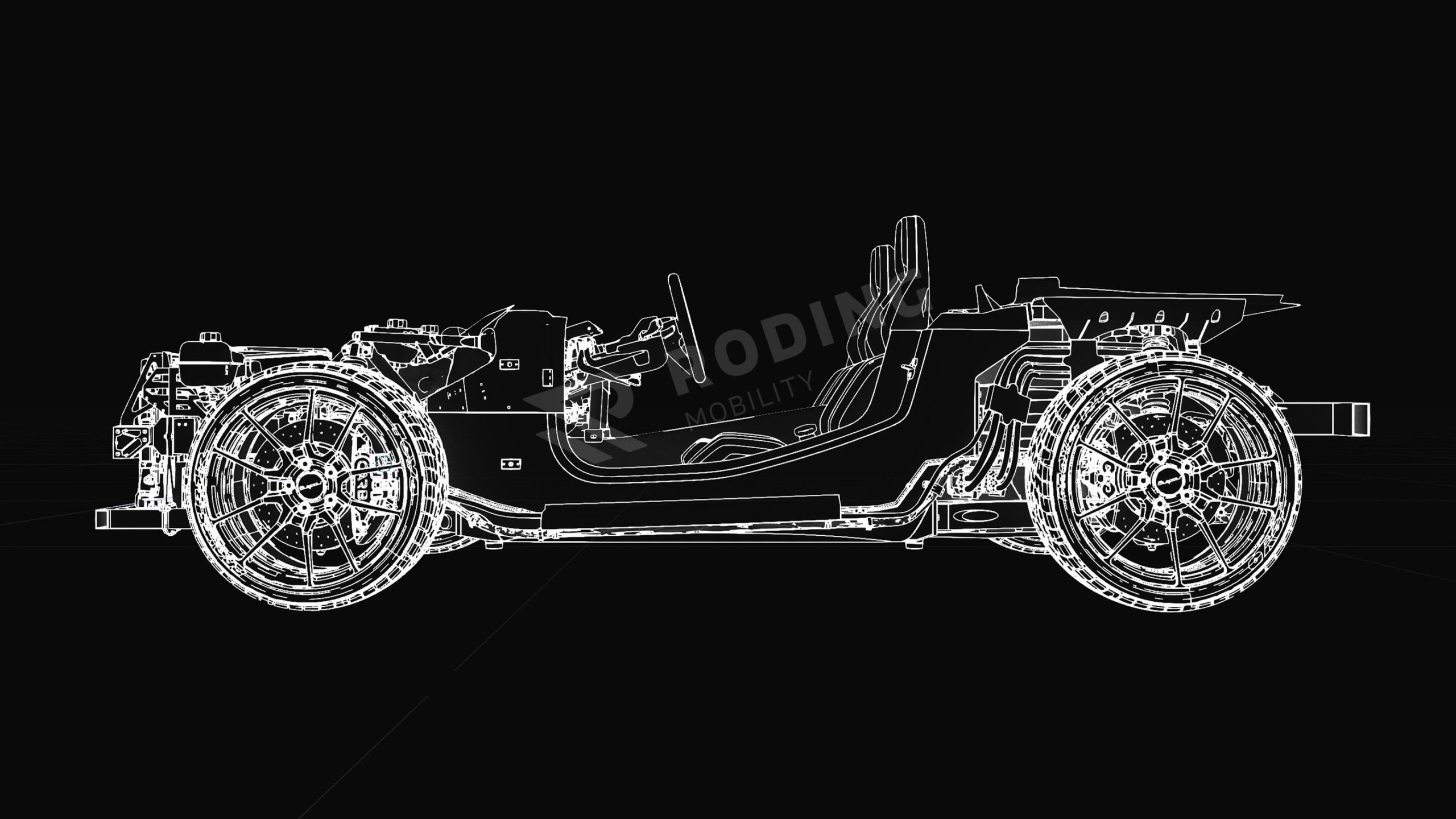

BASE CHASSIS

TEXT BENÖTIGT! I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

BASE CHASSIS

with Roof Installation

TEXT BENÖTIGT! I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

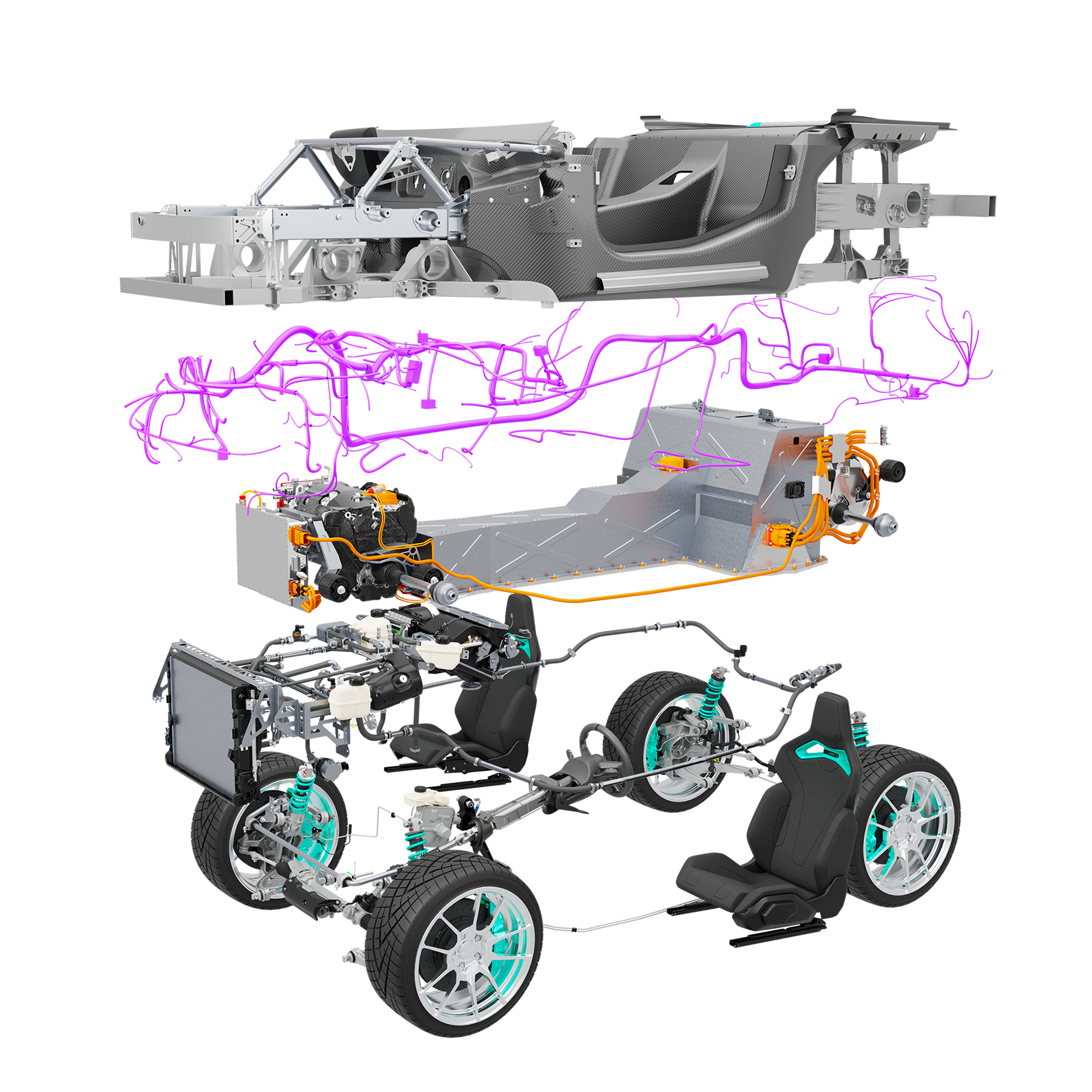

CFRP/Aluminum Lower Structure

- Flexible A-pillarand windshield-frame connection

- Wheel base adjustable with alternative rear frames

400V AWD Powertrain

- Tunnel battery enables low vehicle floor

- Modern, series approved 3-in-1 EDUs

Roding Chassis System

- Roding Mobility E/E Architecture and VCU-Controller-Network

- Roding Mobility double wishbone suspension

- Electrical power steering

- Thermal system for all powertrain components

- HVAC unit incl. A/C circuit

- Body controller for bodywork electrical functions optional available

Specification of Roding EV 2-Seater Platform

| CFRP Base Platform | Base Specification | Typical options (some may require integration engineering |

| Seat Configuration | 2 seater | |

| Lower Body | CFRP tub and aluminium front / rear section | |

| Upper Body | CFRP oder steel frame | |

| Wheelbase | 2445 mm | Wheelbase extension up to 2745 mm |

| Track width | Front 1648 mm Rear 1600 mm | Increased track width up to 1800 / 1750 mm (fr/re) |

| Battery System | 400 V Li-Ion NMC 84 kWh (80 kWh usable) ma power 630 kW (5s) | |

| Drivetrain | AWD 550 kW or RWD 380 kW one motor per axle with single speed gearbox Axle Torque: front 3050 Nm / rear 5690 Nm | RWD 550 kW (available from 2024) AWD 1000 kW (available from 2025) |

| Syspension System | Double wishbone front and rear 3-way adjustable shocks adjustable antirollbars | Lifting System (front / rear) Center Lock Option on wheelhubs / wheels |

| Wheels | Front 245/35 R19 Rear 305/30 R20 | Other tire / wheel sizes |

| Brake System | Front 380 x 36 mm steel with 6 piston caliper Rear 380 x 32 mm steel with 4 piston caliper ABS/ESP System | Carbon/Ceramic braces |

| Charging System | 11 kW AC and 220 kW DC | 22 kW as option available |

| E/E Architecture | Roding Mobility VCU-Network | Roding Mobility Body-Controller for Body- and Comfort functions |

| Example performance depending on Full Vehicle Concept | ||

| Vehicle Top Speed | 245 kph with standard ratio | Bespoke ratio up to > 300 kph |

| Accelerations (with one foot rolling) | 0 - 100 kph: 2.5 s 0 - 200 kph: 7.1 s | |

| Consumtions | App. 20 kWh WLTP |

OurValue Proposition:

12 Months to Prototype and

24 Months to ECE-Small-Series

Why use the RDC2 Driving Chassis

Prototype stage

- First prototype 4 – 6 months earlier

- Lower risks with tested driving chassis

- Greater design flexibility compared to carry over platform from OEM production cars

- Proven chassis and ergonomics package

- Our customers can focus on bodywork styling / engineering

Production stage

- Quicker powertrain and chassis validation / homologation

- No investment in monocoque or chassis tooling on customer side

- Vehicle service could be combined with other manufacturers base don theRDC 2 chassis

- Business case / product lifecycle independet from carry over OEM-platform market cycle